Visual testing is a widely used NDT method, often the first step in inspections because of its immediate results. It helps identify visible flaws on surfaces and inspect less accessible areas. Examinations can be direct or indirect, with tools like magnifiers or boroscopes. The method is valued for its simplicity, speed, and low costs, making it an effective way to assess potential issues and decide which other nondestructive methods may be needed.

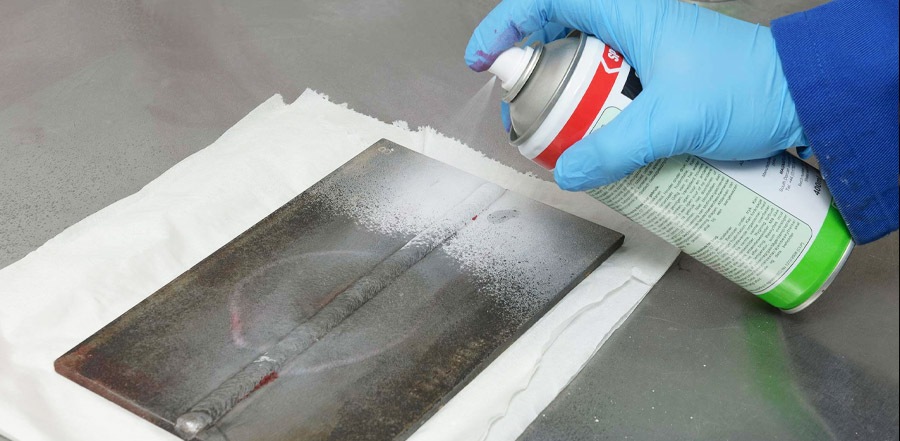

Penetrant testing involves applying a dye penetrant to the examined surface. After a specific penetration time, a developer is applied to highlight any discontinuities open to the surface by utilizing the absorption properties of the developer. This method is used to identify visible flaws and inspect less accessible areas. Examinations can be performed directly or indirectly, using tools like magnifiers or boroscopes. The method is simple, fast, and cost-effective

Magnetic Particle Inspection (MPI) is used to detect surface and near-surface flaws, such as cracks and other discontinuities, in ferromagnetic materials. We offer various types of MPI services using a range of handheld yokes to apply both direct current and alternating current magnetization methods. The types of MPI include dry powder, wet visible, and wet fluorescent methods. It can be used in almost any environment but is limited to ferromagnetic materials like steel and iron.

Ultrasonic testing is based on mechanical waves (ultrasound) generated by a piezo-magnetically excited element, typically operating in the frequency range of 2 to 5 MHz. The process involves the transmission, reflection, and absorption of ultrasonic waves within the tested material. The transmitted wave is reflected by any flaws, and the returning signals help locate these defects. The position of the flaw is determined by interpreting the signals.

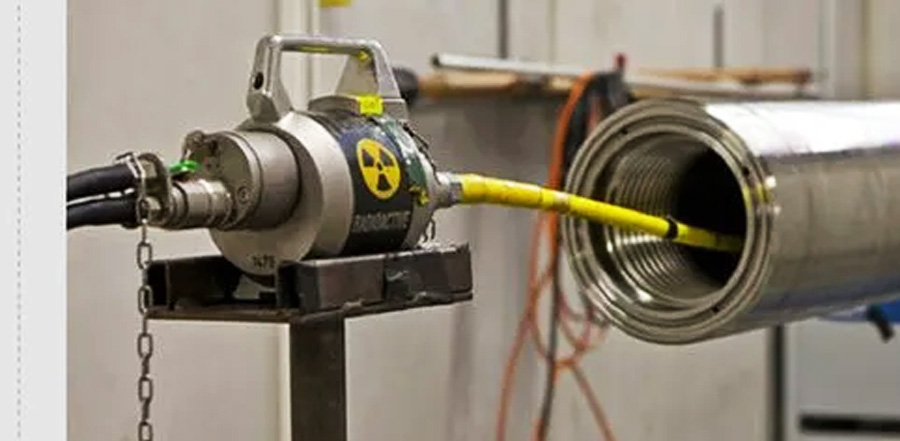

Radiography testing is a common NDT method that uses high-frequency mechanical energy in the form of X-rays or gamma rays to detect internal, hidden discontinuities. It is capable of identifying a wide range of internal flaws in materials, from thin sheet steel to large cast components. This method is effective in detecting internal discontinuities within welds, such as inclusions, porosity, cracks, and lack of fusion. This provide accurate analysis of the location, size, orientation, etc.

PAUT uses multiple transducers to create a phased array, allowing for high-resolution imaging and precise detection of flaws in welds and critical components. TOFD, by analyzing the diffraction of ultrasonic waves from flaws, is highly effective for locating surface-breaking and near-surface defects in welds and thick materials. LRUT, utilizing low-frequency waves, can inspect large areas, such as pipelines and pressure vessels, over long distances, detecting corrosion and other internal flaws.

Eddy current testing is used to detect surface and near-surface flaws in conductive materials. The equipment is highly portable and reliable, capable of identifying very small cracks. The results are instant, making it ideal for on-site testing and plant inspections, where quick and accurate assessments are required.