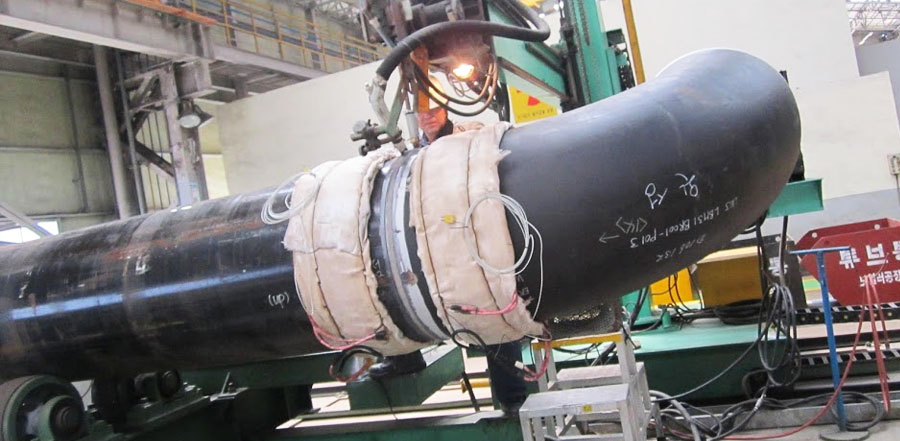

When it is not possible to place an entire component in a furnace for heat treatment due to its size, geometry, or on-site installation, localized post-weld heat treatment (PWHT) becomes the best alternative. MSIQCS specializes in providing localized PWHT using advanced electrical resistance systems with ceramic heating elements. This method ensures controlled and uniform heating, allowing for effective stress relief and structural integrity without requiring the removal of large components.

For large components or multiple items with the same material specifications, furnace post-weld heat treatment (PWHT) is the most efficient and effective method. MSIQCS offers PWHT services using its existing facilities or by providing customized solutions, including both permanent and temporary furnaces, tailored to meet specific project needs. This method ensures uniform heating, precise temperature control, and optimal stress relief, enhancing the structural integrity.

Preheating is the process of heating a material before welding or other heat treatment processes to reduce thermal stress, minimize cracking, and improve weld quality. It is especially important for thick materials and high-carbon steels, as it slows the cooling rate and prevents hardness variations in the heat-affected zone. MSIQCS provides precise preheating solutions using electrical resistance, induction, and gas heating methods to ensure uniform temperature distribution.

Annealing and normalizing are heat treatment processes used to enhance the mechanical properties of metals. Annealing involves heating the material to a specified temperature and then slowly cooling it to refine the microstructure, improve ductility, and reduce hardness. Normalizing is similar but involves air cooling, which produces a more uniform grain structure, enhancing strength and toughness. MSIQCS provides controlled annealing and normalizing treatments for a wide range of materials.

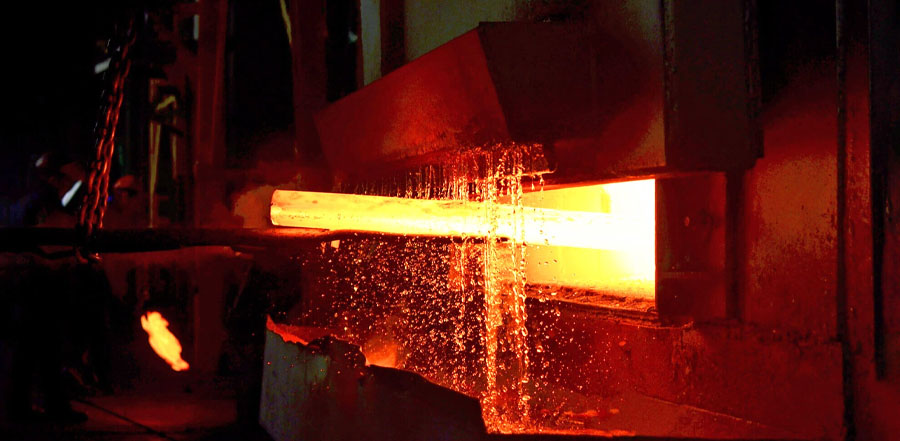

Hardening is a process that increases the strength and wear resistance of metals by heating them to a high temperature and then rapidly cooling (quenching) them in water, oil, or air. This creates a harder but more brittle structure. Tempering follows hardening and involves reheating the material to a lower temperature to reduce brittleness while maintaining the desired hardness and strength. We offer precise hardening and tempering solutions to achieve the right balance of toughness